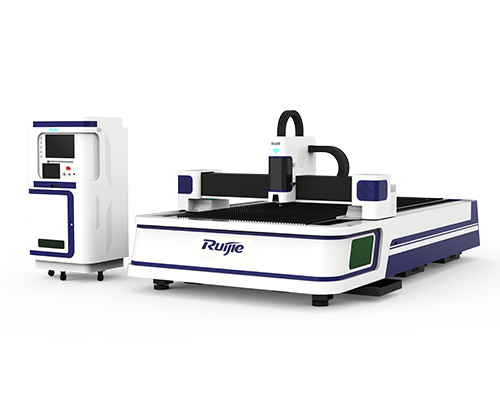

Fiber laser cutting machine is now increasingly used in metal processing industries. It has highly powerful fiber laser beam that works on sheet metals with precise and efficient cutting performance. The laser head will keep 0.6mm to 1.5mm distance with the surface of materials so that the cutting effect is completely protected. The auxiliary cutting gas can be chosen from air, oxygen and nitrogen, however we recommend oxygen and nitrogen firstly for good cutting effect, and depending on what metal types you plan to work with. The residues produced in the cutting process could be blown out by auxiliary cutting gas and collect in the waste collection box below the lathe. Hence the total cutting process is clean and environmentally friendly.

When it comes to metal cutting, plasma laser, CO2 laser and fiber laser all are able to cut metals, but with different cutting thickness, speed, precision and efficiency. The main differences lie in that plasma can be used to cut sheet and thick metals, and it especially works better on thick materials; CO2 laser cutting machine is also suitable for thick metals cutting with higher cost and not very high precision; fiber laser cutter is currently the leading laser cutting solution by virtue of its superior cutting accuracy (0.02mm/min), lower energy consumption, higher productivity and little maintenance.

With development and renewal of technology, fiber laser cutting machine is the best choice on processing metal work, welcome to contact us freely if you have any needs, waiting for you.

Post time: Dec-29-2018