TECHNICAL PARAMETERS

- ModelRJ1330A

- Working Area1500X3000mm

- Laser Output Power200-2000w

- Laser Wavelength1070nm±10nm

- Applicable Material Metal sheet

- Cutting Thickness ≤12mm

- Maximum Cutting Speed30m/min

- Maximum Travel Speed 80m/min

- Equipment Power≤14kw

- Positioning Accuracy±0.03mm/min

- Cooling Modewater cooling

- Supply Voltage and Frequency380V, 50/60Hz Triphase

RJ1330A Standard Sheet Metal Cutting Machine

|

Software1.Support AI/PLT/Gerber formats, accept Mater Cam, Type3 outputinternational standard G code.2.Lead-in/out, cutting compensation, micro-joint, bridging, back entry,gap cutting etc.,3.Multiple piercing methods available, separated laserpower/frequency/ gas type/ gas pressure/ height track can be setduring cutting and piercing,4.WIFI remote control panel |  |

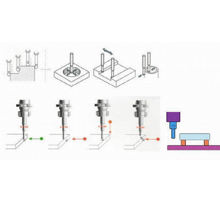

Leapfrog function:highly improve the cutting efficiency. |

|

Photoelectric edge search : fast location and improve processing efficiency |  |

Power control:allowing corners to be cut with a sharp angle |

|

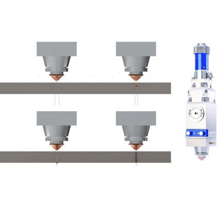

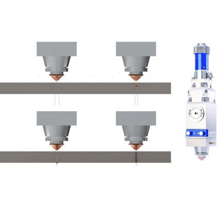

Flying cut: especially for thin metal sheet, fast cut of matrix patterns |  |

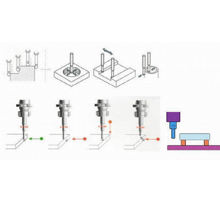

Sprint laser piercing: This helps to keep the optics clean and improves the cutting process by pushing vaporised and liquified material outthrough the kerf, especially for the thick sheet metal |

1. The bed with high rigidity is processed with standard annealing treatment by CNC high temperature furnace to maintain stability of the bed.

2. Superior laser beam quality: – Smaller focal spot – Thinner cutting line – Higher efficiency

3. No gas will be created when fiber is generated. Air as auxiliary gas can help to cut the metal sheet.

4. All kinds of graphics and texts are available for designing and cutting instantly. Easy, convenient and flexible to operate.

1.Low cost and free maintenance for cutting all kinds of sheet metal.

2.Imported original fiber lasers,high and stable function,lifespan is over 100000 hours.

3. Higher cutting speed and efficiency, speed of cutting plate can reach over 30 meters

4.Smooth and fine edge or surface and small distortion;

5.Dedicated software enables graphic or text to instantly designed or processed. Flexible and easy operation.

1. 2 years warranty of fiber laser cutting machine

2. 24-hour full after sales service.

3. Machine lifetime maintenance services though warranty expires.

4. OEM Service Customized and OEM orders are welcome due to our abundant experiences.

RJ1330A Standard Sheet Metal Cutting Machine

|

Software1.Support AI/PLT/Gerber formats, accept Mater Cam, Type3 outputinternational standard G code.2.Lead-in/out, cutting compensation, micro-joint, bridging, back entry,gap cutting etc.,3.Multiple piercing methods available, separated laserpower/frequency/ gas type/ gas pressure/ height track can be setduring cutting and piercing,4.WIFI remote control panel |  |

Leapfrog function:highly improve the cutting efficiency. |

|

Photoelectric edge search : fast location and improve processing efficiency |  |

Power control:allowing corners to be cut with a sharp angle |

|

Flying cut: especially for thin metal sheet, fast cut of matrix patterns |  |

Sprint laser piercing: This helps to keep the optics clean and improves the cutting process by pushing vaporised and liquified material outthrough the kerf, especially for the thick sheet metal |

1. The bed with high rigidity is processed with standard annealing treatment by CNC high temperature furnace to maintain stability of the bed.

2. Superior laser beam quality: – Smaller focal spot – Thinner cutting line – Higher efficiency

3. No gas will be created when fiber is generated. Air as auxiliary gas can help to cut the metal sheet.

4. All kinds of graphics and texts are available for designing and cutting instantly. Easy, convenient and flexible to operate.

1.Low cost and free maintenance for cutting all kinds of sheet metal.

2.Imported original fiber lasers,high and stable function,lifespan is over 100000 hours.

3. Higher cutting speed and efficiency, speed of cutting plate can reach over 30 meters

4.Smooth and fine edge or surface and small distortion;

5.Dedicated software enables graphic or text to instantly designed or processed. Flexible and easy operation.

1. 2 years warranty of fiber laser cutting machine

2. 24-hour full after sales service.

3. Machine lifetime maintenance services though warranty expires.

4. OEM Service Customized and OEM orders are welcome due to our abundant experiences.

APPLICATION INDUSTRY

APPLICABLE MATERIAL

CUTTING SAMPLES

Send us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur